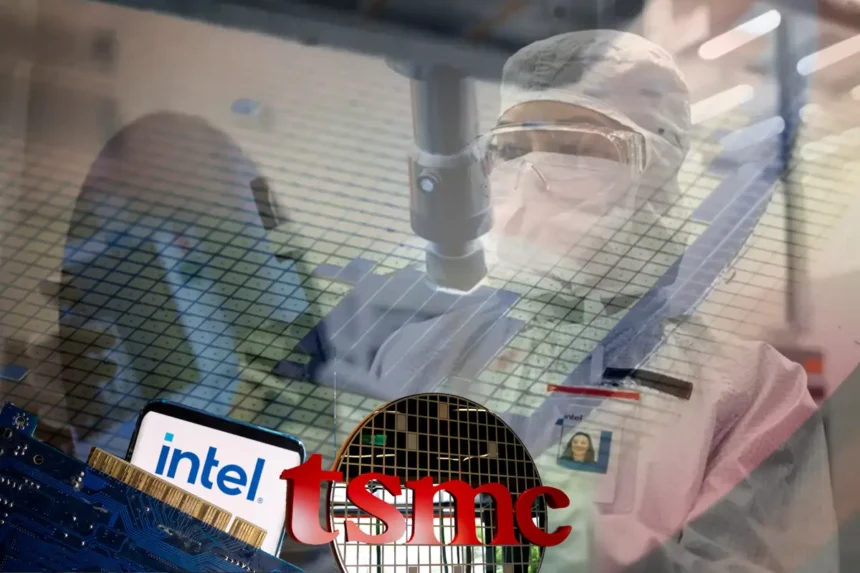

Intel’s foundry business continues to make headlines, particularly with former executives debating whether it should be spun off from the rest of the company. At a recent technology conference, Intel’s vice president of corporate planning and investor relations, John Pitzer, revealed that despite previous plans to reduce reliance on external suppliers, 30% of Intel’s wafers are still outsourced to TSMC.

According to Pitzer, Intel’s strategy has shifted, and the company now views TSMC as a valuable partner, fostering healthy competition between TSMC and Intel Foundry. “We think it’s always good to have at least some of our wafers with TSMC,” Pitzer said. “They are a great supplier.”

Intel’s upcoming Panther Lake mobile CPUs will be built on the company’s 18A process node, but current Arrow Lake and Lunar Lake processors primarily use TSMC-produced silicon, with final assembly and packaging handled at Intel’s US-based facilities. Relying on TSMC’s advanced silicon will likely impact Intel’s margins, as outsourcing production can be more expensive than in-house manufacturing.

Pitzer acknowledged that Intel is still determining the optimal level of external foundry usage, considering targets between 15% and 20%. “We will use external foundry suppliers longer under this new strategy,” he said.

This development comes nearly a year after former CEO Pat Gelsinger expressed hopes of reducing Intel’s dependency on TSMC wafers from 30% to 20%. However, with Intel’s current leadership transition and ongoing challenges, it remains to be seen whether the company will decrease its reliance on TSMC wafers in the near future.

Rumors have circulated about potential partnerships or acquisitions involving Intel’s fabs, including speculation about TSMC’s interest in taking control of Intel’s manufacturing facilities. Amidst the uncertainty, one fact remains clear: 30% of Intel’s wafers are still coming from TSMC, a figure that has been consistently reported over the past two years.